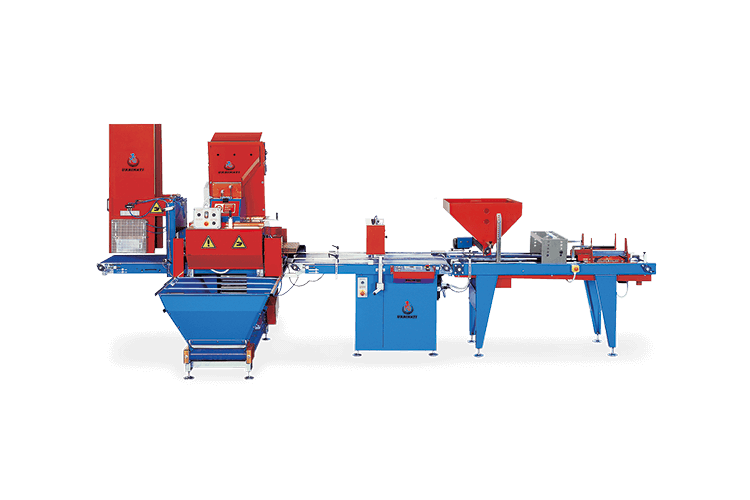

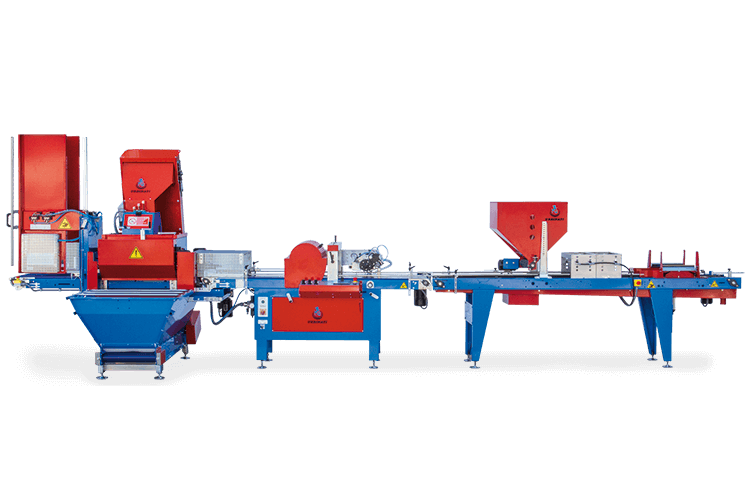

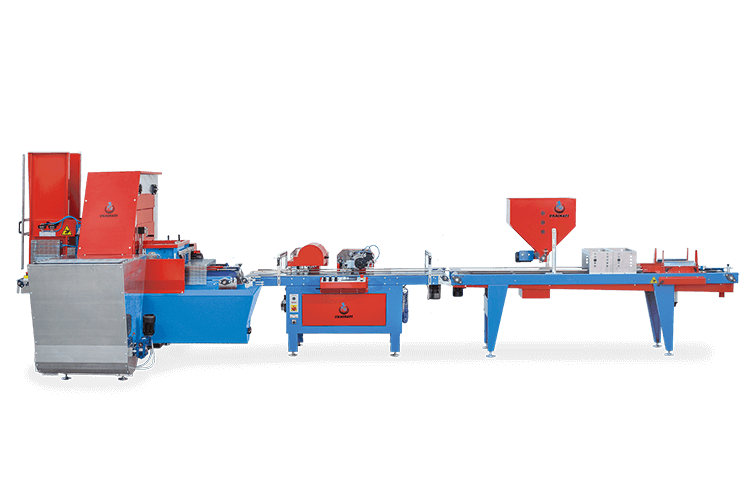

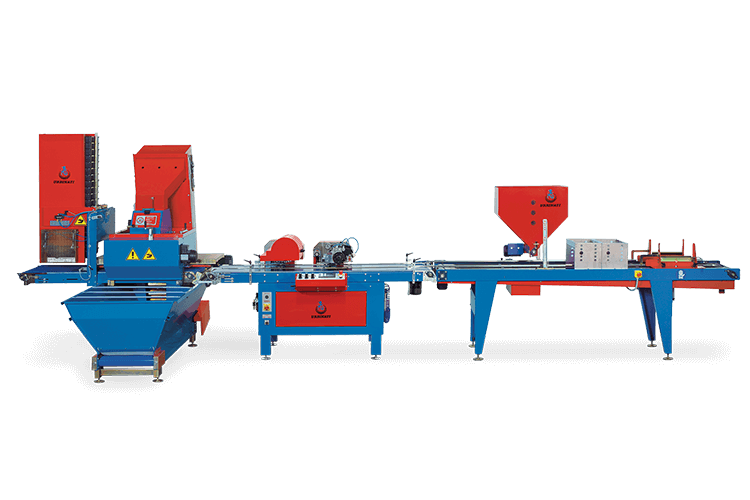

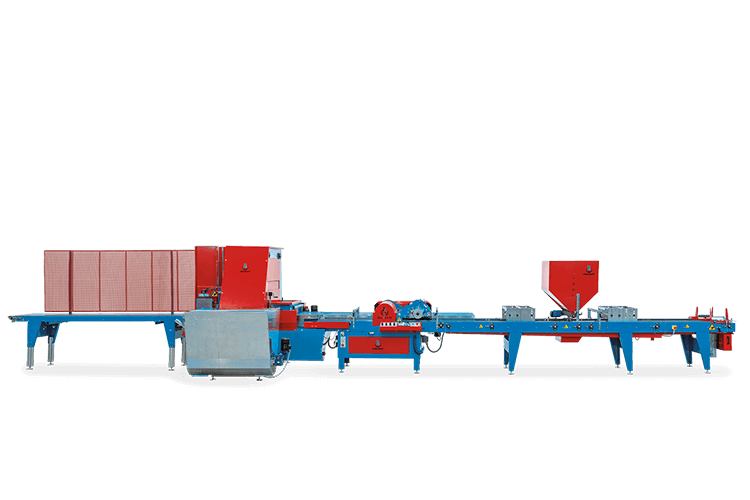

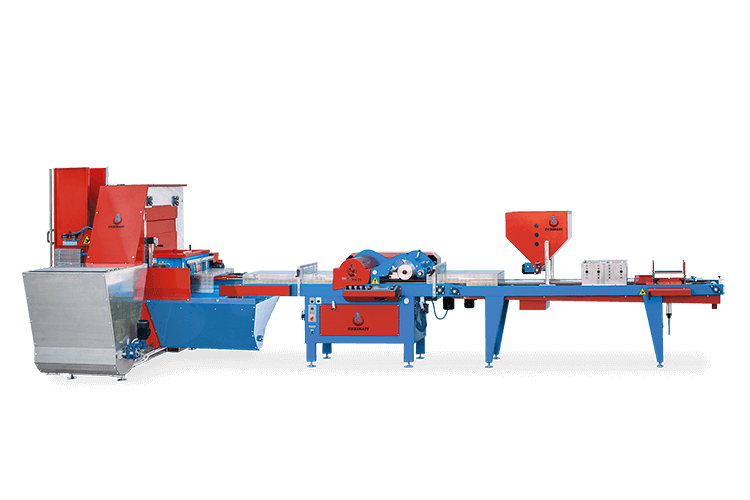

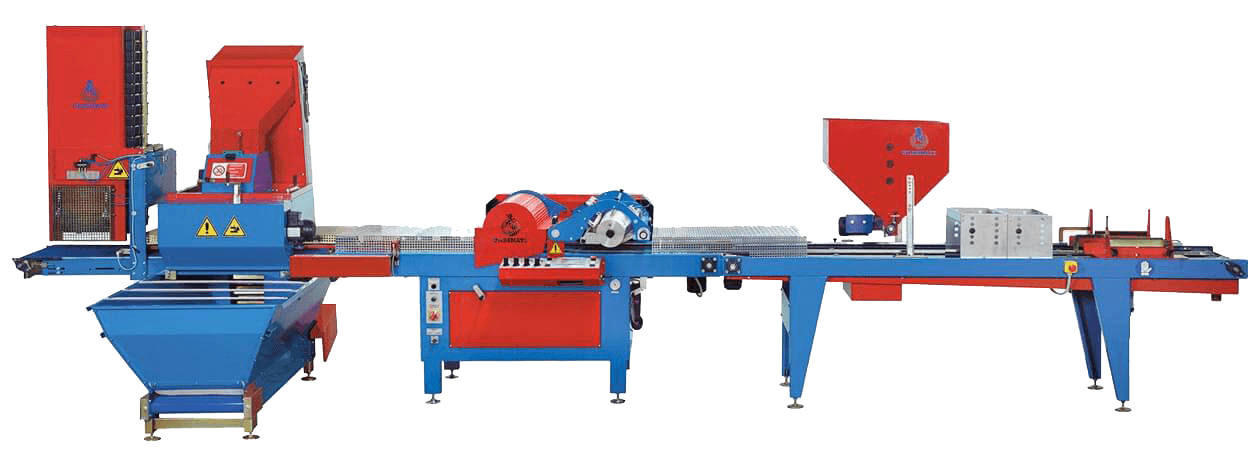

Urbinati BETA65C Compact Seeding line

Urbinati BETA65C Compact Seeding line

- Overview

- Specifications

- Watch Video

- Accessories

- Enquiry

Urbinati BETA65C Compact Seeding line

The drum seeding line BETA65C can reach a production speed up to 800 trays/hour.

The trays advance one next the other into the tray filler, ensuring the maximum filling uniformity in every cell, also in the cells along the edge of the tray. The filling can be adjusted with one single handle and enables a variable filling with soft, medium or high density.

The brush perfectly cleans the trays from the excess soil, which is completely recycled without any waste.

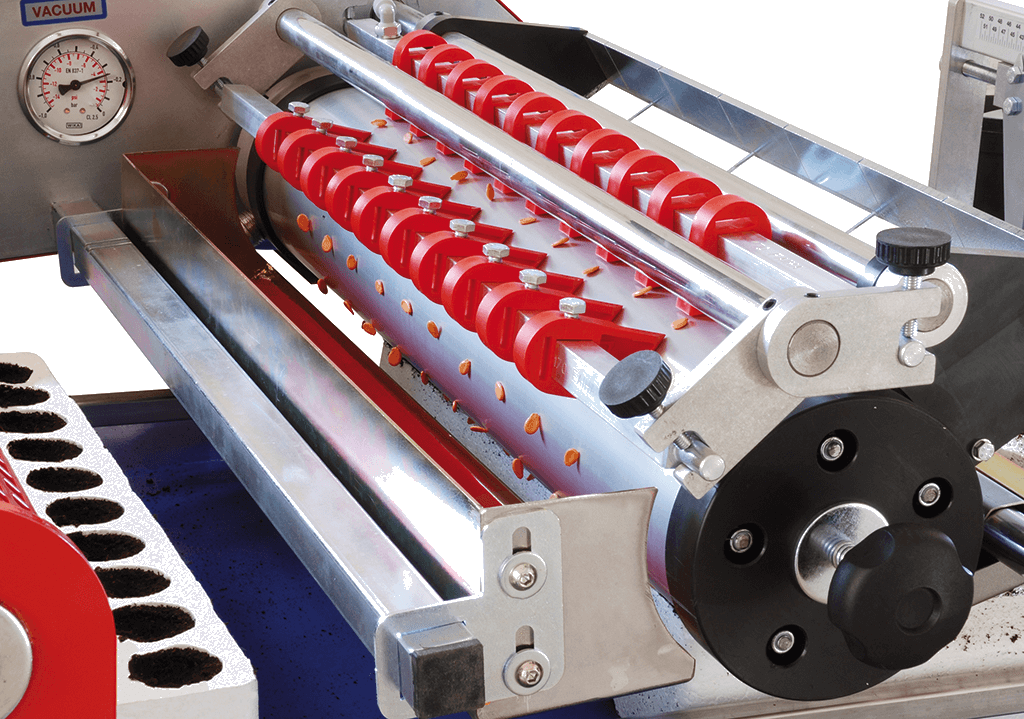

The driven dibble ensures a centred seed positioning in the cell and a perfectly regular shape of the hole.

The engineering on the seeding drum and computer control produce a perfect singularisation with both small and big seeds.

A second seeding drum can be added for multi-seeding or chemical grain dispensing.

Changing the seeds or tray type is fast, thanks to the fast adjustments and the drums are changed without tools.

The drum cover for vermiculite or other grains performs with great uniformity and enables the operator to choose the working width and the quantity of product distributed, to reduce any waste.

Each component of the machine is designed and produced to improve the work of operators, in order to reduce the maintenance of the machine and speed up the seed changes.

Features

- The trays advance one next to the other on the tray-filler belt ensuring maximum filling uniformity in every cell including those along the edge of the tray

- The filling can be adjusted with one single handle and enables a variable filling with soft, medium or high density

- The brushes remove excess soil which is then recycled without any wastage

- The driven dibbler ensures a centred positioning in the cell and a perfectly regular shape of the hole

- The engineering solutions of the seeding group produce a perfect singularisation with both small and big seeds. A second seeding drum can be added for multi-seeding or chemical grains dispensing

- The drums can be changed without any tool

- The drum coverer for vermiculite or other grains performs with great uniformity and enables you to choose the working width and the quantity of product distributed to reduce any wastage

- Each component of the machine is designed to improve the efficiency of operators thanks to fast adjustments, low noise, high quality and strong build to reduce maintenance

- Strong and lasting frame thanks to galvanising and painting with epoxy primer and powder