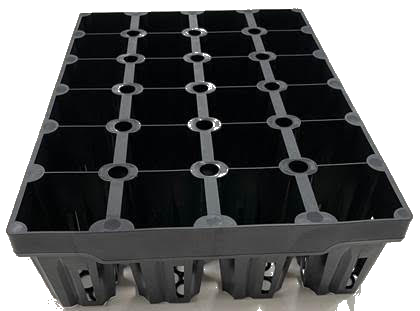

TS-24F Tray

The TS-24F cell tray has been produced in response to interest from New Zealand nurseries growing native seedlings, forestry plantation companies, and leading growers experiencing increasing nursery mechanisation.

It is a multi purpose tray to be used with loose fill growing media.

The trays are made from HDPE (High Density Polyethylene) virgin resin with UV protection.

The distinction between virgin resins and recycled resins is immensely important. Virgin resins are typically more durable on the molecular level than recycled resins, and they perform better over a longer period of time.

The UV protection helps the TS-24F trays have a long life expectancy of fifteen to twenty years use, in line with other trays produced by Transplant Systems. This is also an important distinction when considering thin trays that are destroyed while removing the plants or fail due to UV degradation in the plastic.

Each cell of the TS-24F has a complex architecture, with a volume of 292 cc. The side slots in the cell are designed for aerial root pruning and easy root ball extraction. The top of the TS-24F tray includes generous air vents to help air flow through the tray and the crop canopy, reducing disease due to lack of air movement, and enhancing the aerial root pruning where the roots are effectively “burned” off, causing the plant to constantly produce new and healthy branching roots.

Due to the squat nature of the cells, planting in the field is greatly enhanced, making it much easier for planting teams to plant quickly without the root distortion common with deep cell trays. (See our article "How deep should a container be for tree seedlings")

.

TS-24F cell tray from

Transplant Systems

The TS-24F tray is designed to be placed on wire mesh benching to take advantage of root pruning, but each cell has a carefully

designed media catch grid at the base of the cell, comprising a centre hole with 4 radial holes to assist plant extraction, giving

the opportunity to automatically push the seedling out with five pins, unlike other designs, only allowing a single pin that often

damages the root ball.

The TS-24F tray is designed to be placed on wire mesh benching to take advantage of root pruning, but each cell has a carefully

designed media catch grid at the base of the cell, comprising a centre hole with 4 radial holes to assist plant extraction, giving

the opportunity to automatically push the seedling out with five pins, unlike other designs, only allowing a single pin that often

damages the root ball.

The design of the base of the TS-24F also gives ideal drainage, without recesses accumulating unwanted water, so that the grower retains control of the air porosity of the media

As well as the biological benefits of the TS-24F cell tray, the design and precision incorporates all the modern features required to use

it in automatic machinery also supplied by Transplant Systems. The trays are designed to nest, for ease and economical

transport, but are also designed to be dispensed by machine, and are robust enough to withstand the soil delivery system of high speed

tray filling machines.

As well as the biological benefits of the TS-24F cell tray, the design and precision incorporates all the modern features required to use

it in automatic machinery also supplied by Transplant Systems. The trays are designed to nest, for ease and economical

transport, but are also designed to be dispensed by machine, and are robust enough to withstand the soil delivery system of high speed

tray filling machines.

When using the TS-24F cell tray there is no need to wrap the seedling roots with paper, however the cell designed

for loose fill, works to enhance the root zone, for wrapped seedling, as air movement around and through the paper is improved by the

ribs inside the complex cell design. Paper pots are placed manually, or can be mechanically delivered to the cell due to the

careful design and taper of the cell. The paper pots engage the cell at 4 points in the lower part of the cell leaving air

space  between

the paper walls of the pot and the walls of the cell. Plants that are held over with roots emerging from the paper are still

aerial root pruned due to the overall tray design.

between

the paper walls of the pot and the walls of the cell. Plants that are held over with roots emerging from the paper are still

aerial root pruned due to the overall tray design.

With construction of the TS-24F growing cell designed (a) To improve the root structure thus the quality of container raised

plants. (b) To contribute in lowering the cost of plant handling in the nursery, (c) Improve the plant extraction from the cell, while

reducing damaged root balls and (c) Long life expectancy, the features of theTS-24F cell tray stack up for better results.

Adding to all these benefits, the TS-24F tray has a common foot print to the TS-48F cell tray allowing the same machinery and

the same benching to be used. We know this will help a lot of nurseries already using the TS-48F, as machines need less adjustment when

changing from tray to tray, thereby increasing useful production time.

| Tray dimensions | 385 x 289 x 100 |

| Cell dimensions | 63.5 x 63.5 mm |

| Cell volume | 250 cc |

| Plant density | 217 per m2 |

..