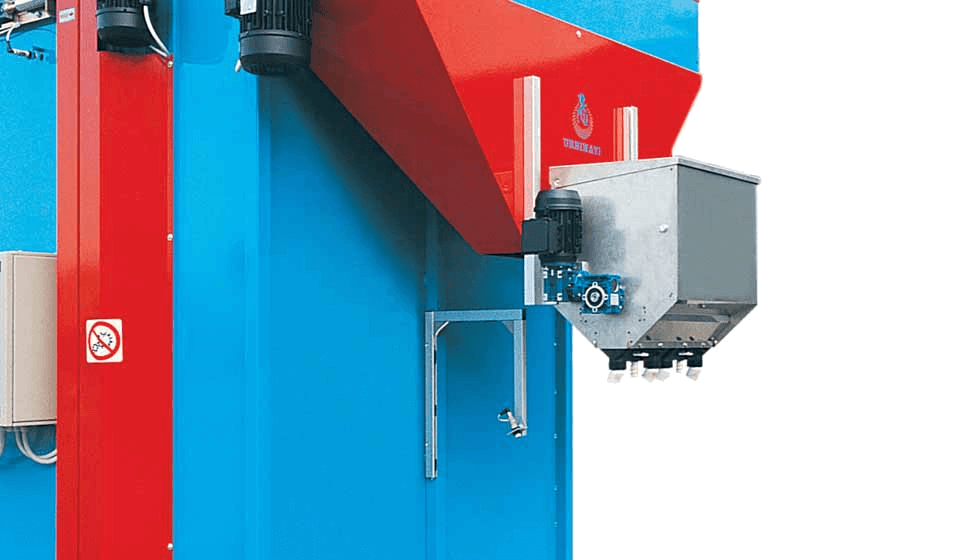

Urbinati Vertical Bale Breaker

Urbinati Vertical Bale Breaker

.jpg)

- Overview

- Specifications

- Watch Video

- Enquiry

Urbinati Vertical Bale Breaker

Many key features make the Urbinati VBB the best big bale breaker on the market. It has a small footprint and vertical peat scraping system. It has doors that close to keep the peat moist, even when not in use. A variable speed lift platform ensures the perfect amount of mix and particle size, with the bale contained in an enclosed area, break out does not produce large amounts of dust.

- Automatic chain tensioners

- Acoustic alarm for completed bale

- Automatic pallet lowering

- Minimum damage to peat using horizontal scraping

- Bale is safely locked behind large doors

- Optical sensor on output for an automatic control

- Visual indicator locating the pallet during the lift

- Output chute with PVC sock reduces dust

- Automatic water unit mounted on outlet with 4 x nozzles

- Process part or complete bales

So how does it work?

A big bale of peat on a pallet is placed into the cabinet. The cabinet door is closed and the start is initiated on the colour touch

screen. The pallet inside the cabinet is raised slowly and the compressed media scraped off the top of the bale by scraper blades

positioned at the top of the machine. The process is electronics controlled, producing the amount of media flow needed for the potting

machine or tray filler. The sensor above the hopper starts and stops the flow of peat as the peat is used, making the delivery completely

automatic. Flow can be stopped at anytime allowing part pallet loads if media to be processed. As the scraping system is controlled

electronically, the output from the bale can produce maximum breakout. Growers report increased peat break out, meaning more pots are

filled, the particle size in the pot is more consistent and the hydration of the peat can be controlled precisely from the first fill.

Growers also report the root development improved root development in pots. After the bale is dispensed the Urbinati VBB lowers the pallet,

and sound the alarm so that a new pallet can be placed in the machine by forklift or pallet jack.