Biofuel

Transplant Systems were contacted by a Bio-fuel company in the Philippines and asked to help. They needed a nursery to grow crops that would supplement the bio-fuel production.

The result was a joint effort between Mal Baxter horticultural consultant, Transplant Systems people, Daniel and Steven in Melbourn and Colin from Auckland. As so many of our projects are, skills came together from many directions to produce a good result for our customer.

The request was to provide a small nursery without too much mechanisation. For us the Nursery was in a remote location, but ofcourse, it was home for our customer.

Initial requirements were scoped up and then orders and delivery were handed over to others in our company, to manage between Urbinati, and the shipping companies. All was going well until the shipping company went into receivership and the ship with our container load of machines sat out of reach for 2 months, waiting for the lawyers to sort out the legal issues.

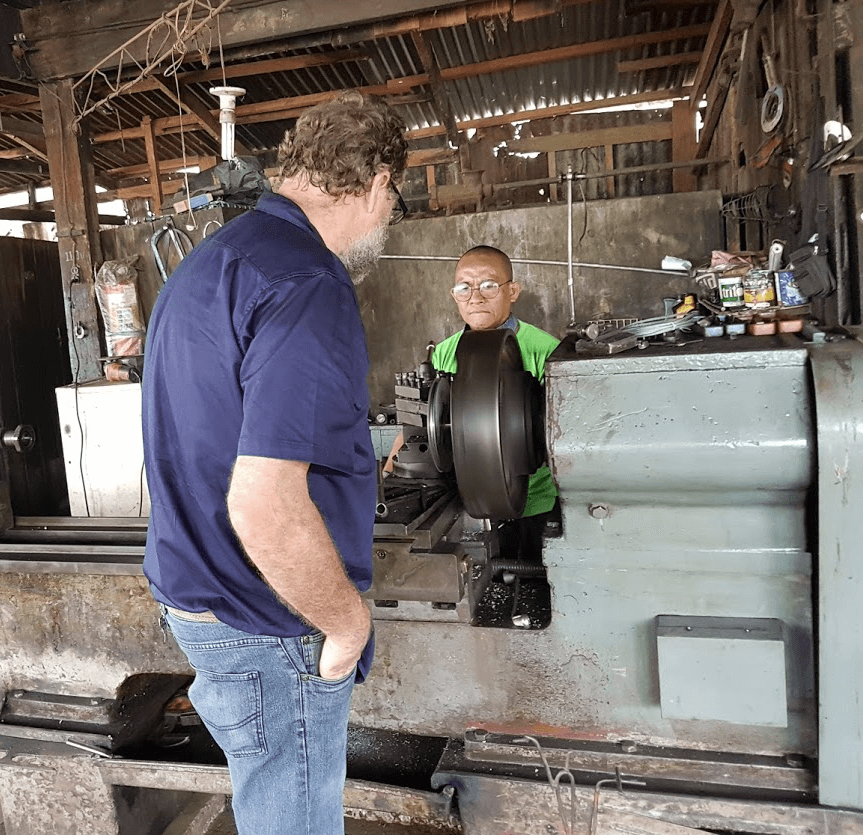

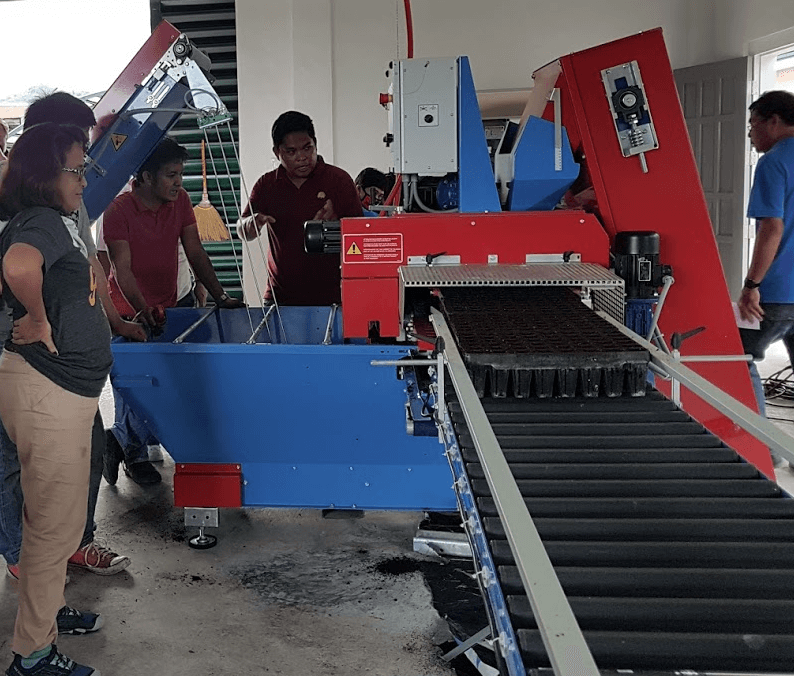

We never gave up, after much effort, the machines arrived and it was up to us to visit to help install the mixer, tray filler, seeder and boom. We love working in the Philippines, a country with such a rich history, and population working and living in more countries than any other population. We always find a warm welcome in the Philippines, and the people keen to get on with the job.

We Supplied:

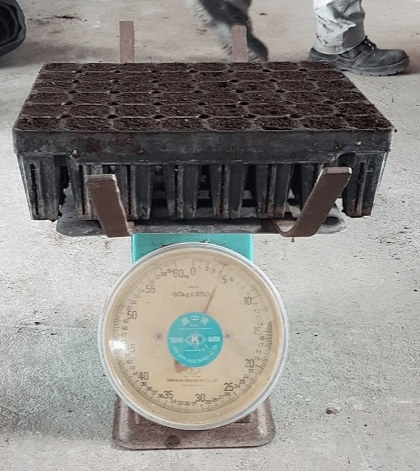

Trays:

The TS-48 tray works for a wide range of crops. The local nursery manager understood the concept of side slot trays and aerial root pruning. The trays are all placed on raised benches, to grow a seedling that has a great root structure that is primed to grow as soon as the seedling is planted out. The plants grown in our TS-48 have as good a root structure, if not better, than in their "natural" way of growing without the Mechanical pruning that slows the plant just before it needs to be ready for transplanting . No chemical root pruning, and no Plastic Bags in this nursery, and no wast plastics, the trays are robust for use many times. With the TS-48 tray the planting season, and planting conditions are extended.

Urbinati Mixer

The nursery manager need to be able to produce the soil blends that were appropriate to the area from locally sourced ingredients. The

Urbinati mixer gave the flexibility to do this, but also had the added advantage of fast mixing, ability to add water, and the automatic

discharge into the hopper of the tray filler.

Tray Filler

The RC65 tray filler was perfect for the tray and for and for the mix that was in use. Because there was a desire to use some local labour in the nursery the trays are feed into the tray filler and removed by hand.

Seeding

The seeder was a small SF seeder from Urbinati. While it is a very simple technology, it can handle wide renge to seed and trays.

Cover and watering

A simple drum vermiculite coverer on the same frame as the watering unit was supplied as the final part of the tray filling and seeding system.

Not our fastest seeding line supplied but certainly meet all the requirements.

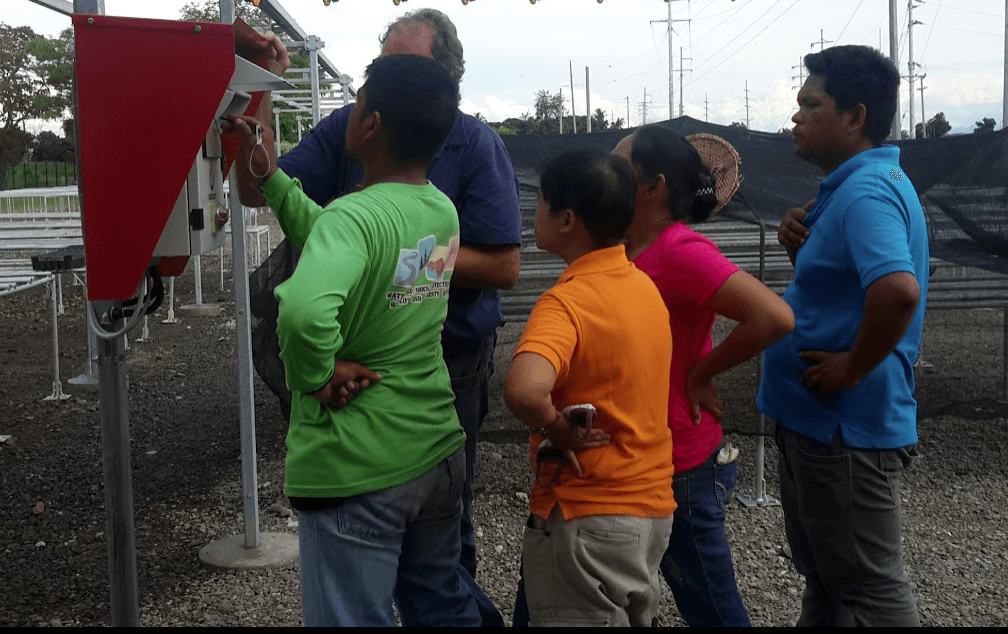

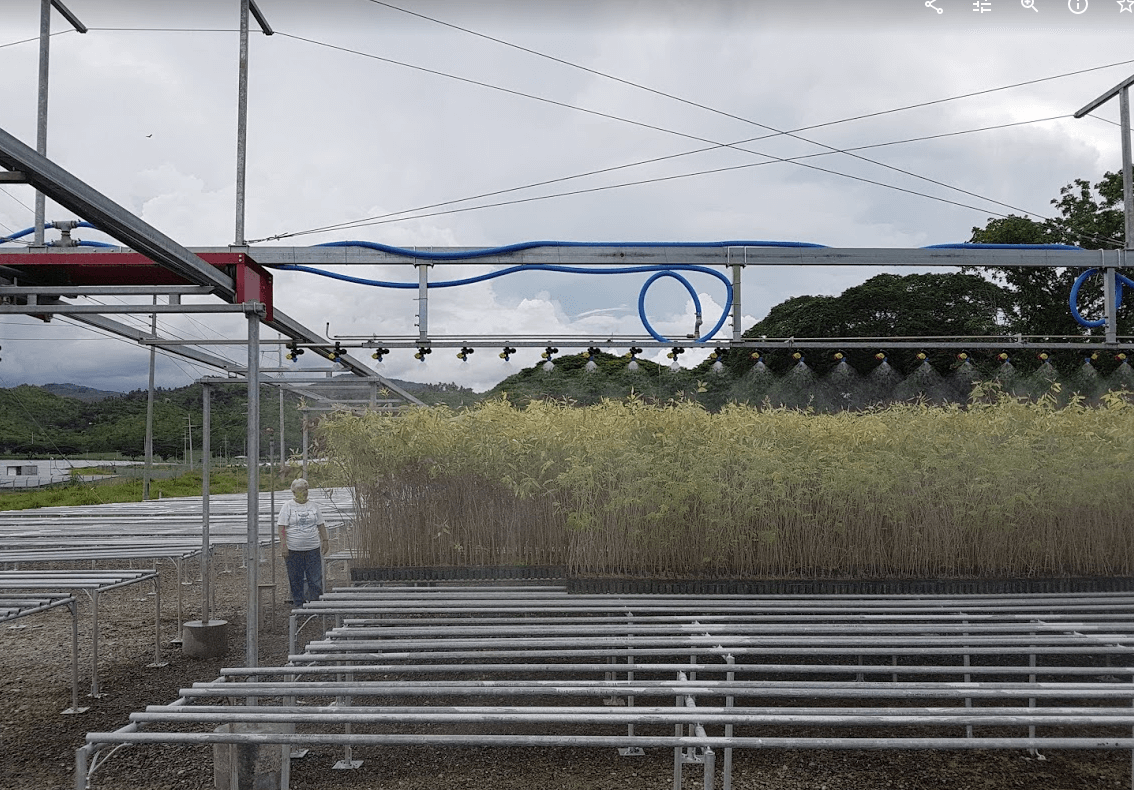

Outside boom.

For the irrigation we supplied the latest Urbinati irrigation boom. The system is a wide boom with a twin post.

Some photos' from location: