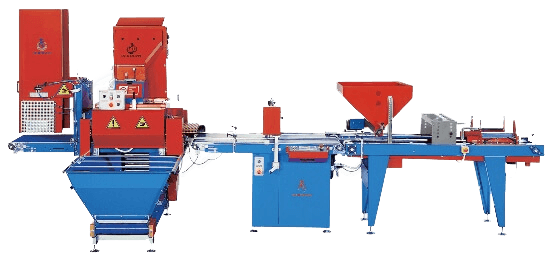

Urbinati KAPPA65C Seeding Line

Urbinati KAPPA65C Seeding Line

- Overview

- Specifications

- Accessories

- Enquiry

Urbinati KAPPA65C Seeding Line

The row seeding line KAPPA65C compact can reach production up to 2400 rows/hour.

The trays advance one after the other on the tray filler belt, ensuring maximum filling, and uniformity in every cell, also in those

along the edge of the tray.

The filling can be adjusted with one single handle and enables a variable filling with soft, medium or high density.

The brush perfectly cleans the trays of the exceess soil.

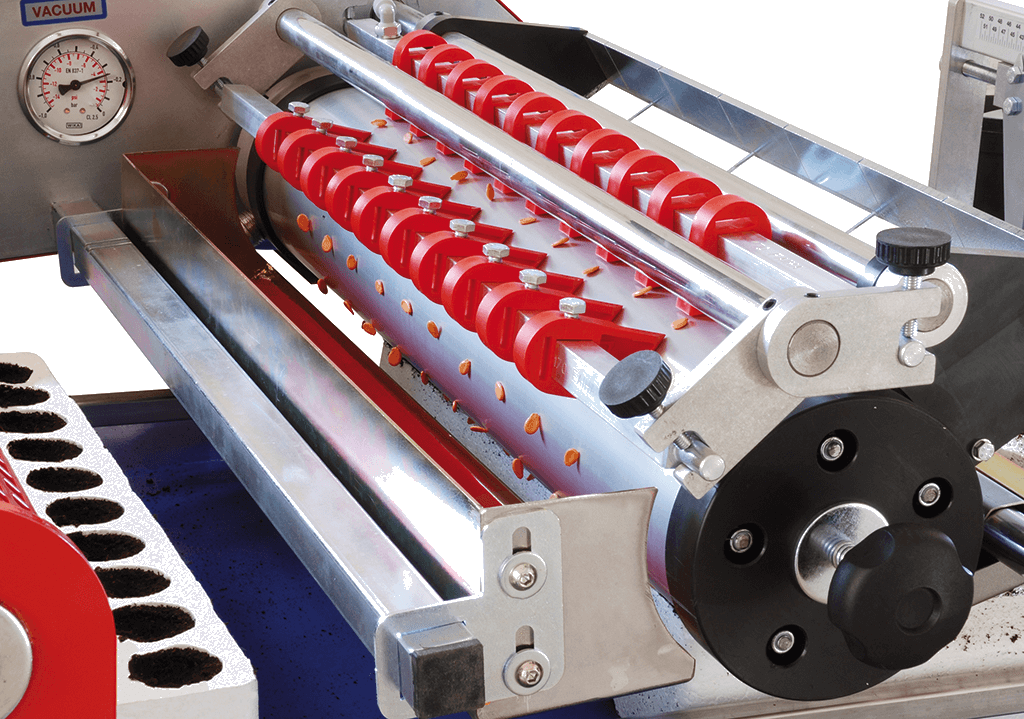

The automatic row seeding group, with electronic control, allows the operator to deposit one or more seeds in the same cell with a perfect

singularisation of both small and big seeds.

Different kinds of nozzles are available as accessories to satisfy any requirement (silicone, multi-seeding, etc.).

Control panel for data display, programming, production and diagnostic can store up to 99 seeding programs.

The pneumatic vibrator in the seed holding plate improves the working of the machine, which can also perform well with a small quantity of

seeds.

The drum coverer for vermiculite or other grains performs with great uniformity and enables the operator to choose the working width and the

quantity of product distributed, to reduce any waste.

Each component of the machine is designed and produced to improve the work of operators, in order to reduce the maintenance and speed up the

seed’s change.

Compact, simple and versatile, the Kappa automatic row seeder has nozzles with electronic control that allows you to deposit one or more

seeds in the same dibbled hole. A great little seeding line for progressive New Zealand plant propagators.

- Trays advance one-after-the-other on the tray-filler belt, ensuring maximum filling, and uniformity in every cell, also in those along the edge of the tray

- Filling can be adjusted with one single handle and enables a variable filling with soft, medium or high density

- The brushing group perfectly cleans the trays of the excess soil

- Automatic row seeding group, with electronic control, allows the machine to deposit one or more seeds in the same cell with a perfect singularisation of both small and big seeds

- Different nozzles are available as accessories to satisfy any requirement (silicone, multi-seeding, etc.)

- Control panel for data display, programming, production and diagnostic can store up to 99 seeding programs

- Pneumatic vibrator in the seed holding plate improves the machine which can also perform well with a small quantity of seeds.

- Drum coverer for vermiculite or other grains performs a great uniformity and enables you to choose the working width, and the quantity of product distributed, to reduce any wastage

- Each machine component is designed to improve the work of operators, thanks to fast adjustments, low noise, high quality and strong build to reduce maintenance

- Strong and lasting frame thanks to galvanising and painting with epoxy primer and powder