Urbinati Drum Seeding Systems Mechanical

Urbinati Drum Seeding Systems Mechanical

- Overview

Urbinati Drum Seeding Systems Mechanical

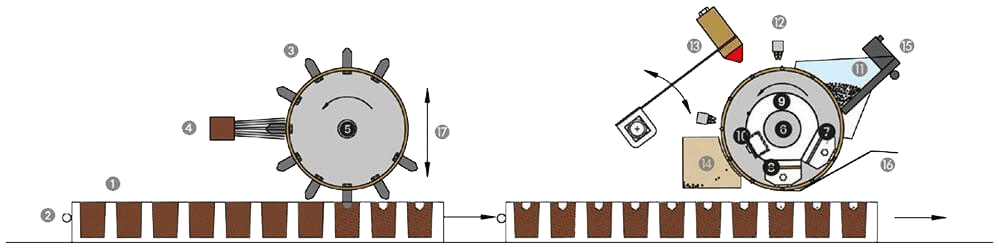

1) Tray.

2 ) Tray advancement bar.

3 ) Aluminium pins with different diameter and form according to the cell and the seeding needs.

4 ) Polypropylene brush for the soil cleaning between the pins.

5 ) Driven dibbler synchronized with tray advancement.

6 ) Seeding drum diameter 169 mm.

7) High pressure room for nozzle cleaning.

8) Low pressure room (0,2 bar) for seed drop. singulation.

9) Vacuum for seed suction.

10) Air compensation tank for the seed drop.

11) Seed holding plate of transparent methacrylate, oscillating to distribute uniformly the seed.

12) Double blow bar with more holes for the seeding singulation.

13) Hammers with adjustable speed: the produced vibration moves the seed to the hole centre.

14) Seed recover plate.

15) Vibrator on the seed holding plate. It optimizes the catching of the big-sized seeds and facilitates the seeding with small quantity of

seeds. Scraper blade.

16) Drums with height adjustment.