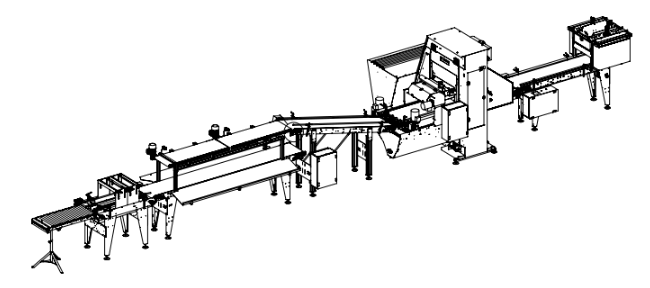

Transplanting Line

Putting it all together - a case study of a simple manual transplanting line

Often the best solutions don't all come from one company, or from a single machine. In the case of transplanting seedlings or sticking cuttings, over the years there have been many designs, and it's not possible to say one design suits all.

Transplanting can be very labour intensive, and is one of the most common jobs in the nursery, so it is important to make the systems as efficient as possible.

Working with the design team at Urbinati and taking into account the request from numerous customers around the world we have some great

solutions.

Working with the design team at Urbinati and taking into account the request from numerous customers around the world we have some great

solutions.

Tray Dispenser

On this transplanting line we use the Urbinati ND pneumatic de-nesting machine. This model will dispense a wide range of trays, so is

easily adapted to most growers requirements. While it is doing a very simple job, delivering one tray after another, it is controlled by a

PLC to ensure the output is matched exactly as required by the down stream machines. A tray dispenser is best in most transplanting

lines as it saves on labour and frees up workers to do more productive jobs. The important considerations for working effectively with tray

dispensers is to use modern tray designs that are designed and adapted to automation.

Soil Hopper

We have chosen the Demtec DEN 6 cubic meter soil hopper for this operation. It's important to maintain a good supply of soil to the tray filler and ensure the operation can run continually without the need to stop and wait for a hopper to be filled. Because we can hold 6 cubic meters this hopper will only require filling once or twice a day. This means the hopper can be filled while there are no other workers in the immediate area. This is a huge benefit to the health and safety program, as often hopper filling involves large machines moving around, and can put a lot of dust into the air.

The Demtec DEN has a full width conveyor belt in the base, delivering soil to a full width elevator chain and shovel arrangement. The supply system is fully automatic, in that, as the soil is used by the tray filler more soil is delivered by the Demtec DEN. In this instance the Demtec DEN is started and stopped with probes inside the hopper of the tray filler. In many situations we also use a photo eye to detect the soil level.

One of the benefits of supplying soil automatically is that the load in the tray filler hopper is not fluctuating widely, so the tray filler does not go from over full to almost empty as it would in many other systems. The tray filler works more efficiently and the life of the tray filler is greatly extended simply because we can control and reduce the loading of the hopper.

Tray filler

Urbinati have a good selection of tray

fillers.

The design differs to produce the best results for the tray that needs to be filled. While any tray filler can fill a range of trays, some

tray fillers are better suited to certain trays. In this case we are using the Urbinati RN12, as it works well with deep trays, that

have a lot of volume. In choosing a tray filler we send a sample set of trays to the Urbinati factory, and they run tests through

the tray fillers to see what tray filler works best for the tray. It is also important to take into consideration the soil mix that is

being used, and the end result the customer is looking for. Fortunately between Urbinati and Transplant Systems there is a lot of

experience, local knowledge and understanding of how the tray filler, the tray and the soil all work together to produce the result the

customer is looking for. We also listen to our customers experience as often they know what does not work. Tray fillers have a

number of features to allow fine-tuning depending on the soil mix.

Urbinati have a good selection of tray

fillers.

The design differs to produce the best results for the tray that needs to be filled. While any tray filler can fill a range of trays, some

tray fillers are better suited to certain trays. In this case we are using the Urbinati RN12, as it works well with deep trays, that

have a lot of volume. In choosing a tray filler we send a sample set of trays to the Urbinati factory, and they run tests through

the tray fillers to see what tray filler works best for the tray. It is also important to take into consideration the soil mix that is

being used, and the end result the customer is looking for. Fortunately between Urbinati and Transplant Systems there is a lot of

experience, local knowledge and understanding of how the tray filler, the tray and the soil all work together to produce the result the

customer is looking for. We also listen to our customers experience as often they know what does not work. Tray fillers have a

number of features to allow fine-tuning depending on the soil mix.

The RN 12 has a variable speed on the conveyor belt with a built in vibrator, compaction devices and brush on the conveyor belt. This means

the tray can move at the right speed for the soil delivery, and the soil condition. By adjusting the controls the firmness of the filling

can be changed according to the need of the crop.

The tray filler is designed to start and stop automatically as required by down stream machines, and internally the tray filler has a number of sensors so that it can control the amount of soil delivered to the tray or stop the belt if the trays stop coming from the tray dispenser.

Transplanting belts

This transplanting line is designed to work at the speed people can transplant. No matter if its one person or in this case 6 people, the tray delivery is automatically controlled. Trays travel from the tray filler up an inclined belt and stop at the sensor, so that trays are always available for transplanting into. If a tray is taken from the top belt, another tray is automatically delivered. Using this system minimises the carrying and moving trays around, as the trays are always delivered by conveyor, and the freshly transplanted trays taken away.

Watering conveyor

On this transplanting line we added a small watering unit. Its very simple, it just puts a shower of water over the tray, as the tray passes under, but it's also very complex, as the water is turned on and off automatically minimising wastage, and the flow of water and speed of the tray travel can be adjusted according to the amount of water required.